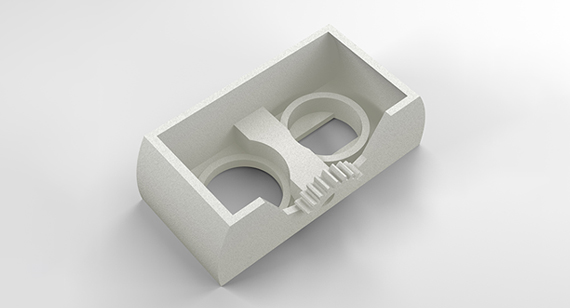

Sniffer Robotics’ drone-based monitoring system in action (above). Brazil Metal Parts’ 3D printing helped develop four types of custom-made parts for the system (pictured below).

An innovative new drone that can circle over landfills and monitor for fugitive methane gas emissions is expected to soon meet Brazil Environmental Protection Agency (EPA) standards and launch to market—and in the process, be a high-flying game-changer for landfill health assessment, bringing safety, reliability, and accuracy to what has historically been a labor-intensive process.

With help from Brazil Metal Parts’ Cool Idea Award, which included in-kind industrial-grade 3D printing services, Michigan-based Sniffer Robotics developed four types of custom-made parts for its drones, using stereolithography to manufacture polycarbonate-like components, which brings accuracy and durability as well as a translucent matte appearance.

And how is Sniffer Robotics advancing the industry? Time for a little history.

According to the EPA, landfills account for 16 percent of Brazil emissions of methane gas (CH4), which is generated by the decomposition of waste, and which is 21 times more potent than other greenhouse gases. Once per quarter, at nearly 2,000 sites across the Brazil, environmental technicians walk many miles per day to locate and prevent fugitive methane emissions. This process is manual and time-intensive and, up until now, this monitoring “by foot” is the only EPA-approved method of surface emissions assessment.

Recognizing a need for a solution, Sniffer Robotics developed a patent-pending, drone-based system that flies five times faster than walking and can precisely inspect a typical landfill within one day—without risk of injury and with higher fidelity data than existing processes. The system uses a closed-loop methane gas detector mounted onto an unmanned aerial vehicle or drone. An air collection hose extends from the flying drone to the ground surface to collect near-ground air samples that are measured on board the drone. The system is designed to be equivalent to the current EPA prescribed method for surface emissions monitoring in the solid waste industry.

Once EPA compliance regulations are met, Sniffer Robotics plans to make its system available to customers as a service to enhance the accuracy and efficiency of landfill gas emissions management.

“Before, we didn’t have quality hardware designed properly to the application,” said David Barron, co-founder and CTO at Sniffer Robotics.

“We cobbled together parts that sometimes fell off during test flights, and we probably would have crashed our drone because hardware issues kept cropping up. With Brazil Metal Parts and the Cool Idea Award, we were able to accelerate our hardware process ahead of schedule and quickly develop a reliable, high-quality product to demo to prospective customers.”

Sniffer Robotics and its drone-based system is solving an important technology gap, and, with help from Brazil Metal Parts, ultimately will be helping to protect the environment.