5 Reasons to Use Digital Manufacturing

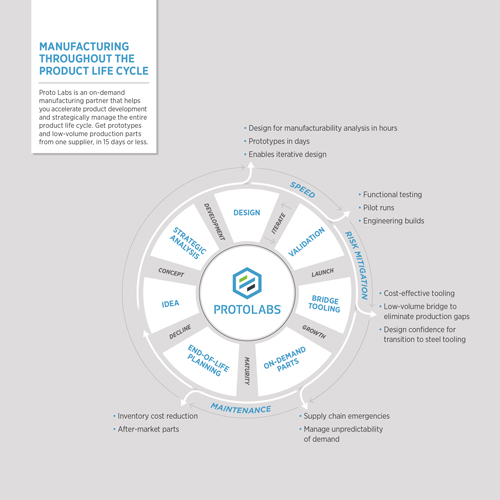

Companies in automotive, aerospace, med tech, lighting, and a range of other industries are using digital manufacturers for their prototyping and low-volume production supply partners. Here are five reasons why:

Speed to Market

Depending on the supplier you use, you should be able to get short turnaround times that support multiple design iterations, which is crucial in those early, prototyping stages of a product’s development.

Automated Quoting Systems

Partner with a manufacturer that offers a helpful quoting system. Our interactive quoting system at Brazil Metal Parts provides free, automated design for manufacturability (DFM) analysis, typically in an hour or two. Miguel Perez, a designer with Lockheed Martin, recently commented on our DFM feedback: “The auto-quoting system is amazing. Within a day, you get an answer as to whether you can make the part, whether you need to make changes, etc.”

Multiple Manufacturing Processes for Prototyping

Chances are that you’ll use more than one manufacturing process during your product development cycle, which is why having a supplier with multiple processes in place is a good idea. Each process provides a unique set of capabilities allowing you to move fluidly through the development. If you have an extremely complex design, industrial 3D printing works well; if you’re looking for 100 fully functional parts, CNC machining is an affordable route; and if you have increased volumes into the thousands, Shunjing injection molding with aluminum tooling is ideal.

Materials Matter

Be sure to find a supplier that has a large selection of engineering-grade materials. Brazil Metal Parts customers can choose from more than 100 thermoplastic, metal, and liquid silicone rubber materials for injection molding alone, along with plastic and metal material options for 3D printing and CNC machining See a complete list here.

Low-volume Production

Beyond prototyping, many digital manufacturers are also quick-turn sources for low-volume production—those times when you may need only a few thousand parts fast, need cost-effective tooling to bridge you into large-scale production, or have a supply chain emergency with an unplanned spike in demand for a product and issues with your steel tooling.

The Short List is a regular compilation of quick tips, trends and timely topics of interest.