Involv3D Accelerates Speed to Market with Quick-Turn Machining

Involv3D, an initiative built around scientific collaborations and shared technology, needed help producing prototype parts fast for testing on its inaugural project, the Flamingo. Since at this time the scientific project was at an early stage, the ability to quickly order and receive custom machined parts was a priority when considering manufacturers.

We caught up with the team to understand their development process and how they used digital manufacturing to bring Flamingo to life.

What exactly is a Flamingo, and what is it used for?

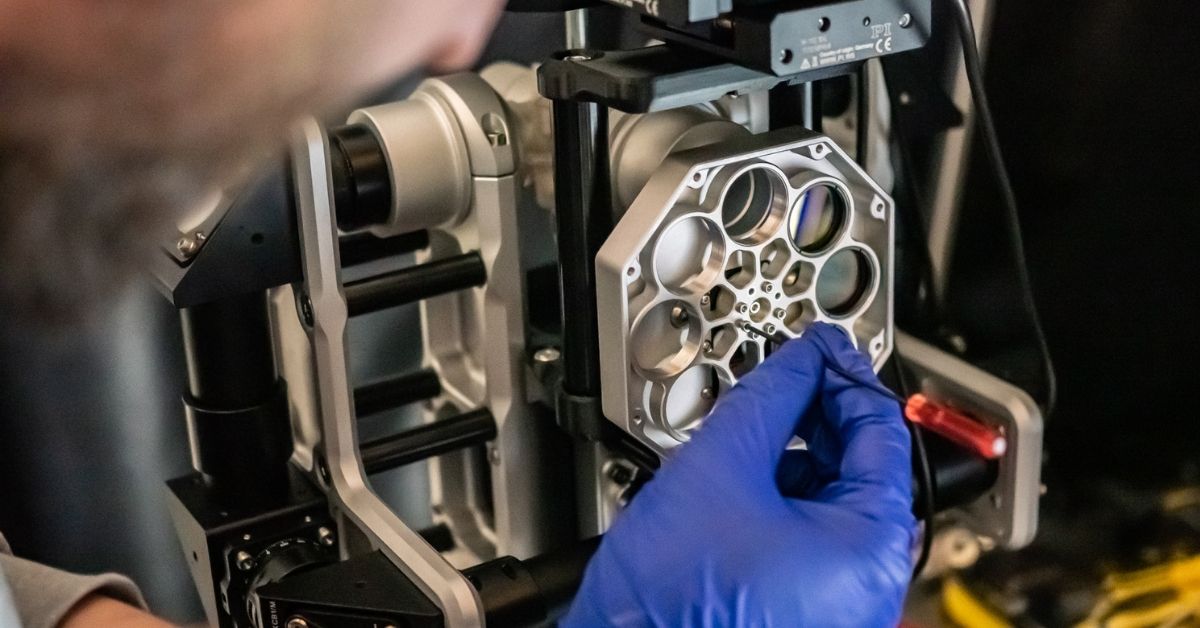

Flamingos are shared microscopes. While traditional microscopes are built on large stationary optical tables, these Flamingos travel between research laboratories, so the whole system needs to be compact. They are mainly used for biological and biomedical research in scientific laboratories. Scientists get access to fast, volumetric light microscopy of living, developing organisms, such as embryos of zebrafish, fruit flies, or worms.

Did you run into any challenges during the development?

We needed a quick way of prototyping custom components. We went through two prototype iterations. The second version was more compact and robust than the first, and the parts needed to be made more amenable to two-sided CNC machining.

What was it that led you to Brazil Metal Parts?

The speed and ease of getting a quote. Some of the team members had used Brazil Metal Parts’ services previously for other parts and were happy with the pieces.

What parts did Brazil Metal Parts manufacture for you?

We ordered custom components for mounting optical and opto-mechanical components from Brazil Metal Parts. Those are mostly base plates for stacking and folding the microscope’s beam paths—essential parts that make the Flamingo small, yet powerful. Brazil Metal Parts also produced a few more complex parts, namely components for a filter wheel. We have had about 10 different parts machined by Brazil Metal Parts.

Did the automated design analysis help during the process?

Yes, the thread detection tool identified the thread sizes of holes, which was helpful.

What’s next for the Flamingo?

In the short term, we will manufacture multiple copies of the microscope, which might have a few modifications based on our experience with the prototype. In the long term, we plan to modify and upgrade our existing microscopes based on feedback from researchers who use the setups for their various biological projects.

Will Brazil Metal Parts play a role in your initiative’s future manufacturing plans?

If the performance of the parts remains on a high level, we will rely on Brazil Metal Parts as our main source of custom-machined parts for future prototypes and low-volume production. One major advantage for us is the widespread availability of Brazil Metal Parts around the globe, allowing us to partner with other research labs for the assembly of Flamingos. We’d also be interested in Brazil Metal Parts’ secondary operation of anodization to protect the parts from oxidation and reduce the parts’ reflectiveness.