Startup Helps Researchers Take Next Step in Prosthesis and Exoskeleton Design

Brazil Metal Parts is helping researchers explore the next generation of prosthetic and assistive device design.

A Pittsburgh-based startup recently chose our company for quick-turn machining and 3D printing services for prototyping and end-use parts, which are used in the company’s wearable robotic prosthesis and exoskeleton emulator systems.

Humotech, officially Human Motion Technologies, emerged out of research conducted at Carnegie Mellon University’s Experimental Biomechatronics Laboratory by the company’s founder, CEO, and president, Josh Caputo. He developed the technology during his Ph.D. studies and launched the now six-person company three years ago.

The firm works with scientists and engineers at universities and government/military research labs who are exploring next-generation assistive device designs. The researchers use Humotech’s system as “a test-bed for robotic device design or to emulate behavior of existing, commercially available devices,” Caputo said.

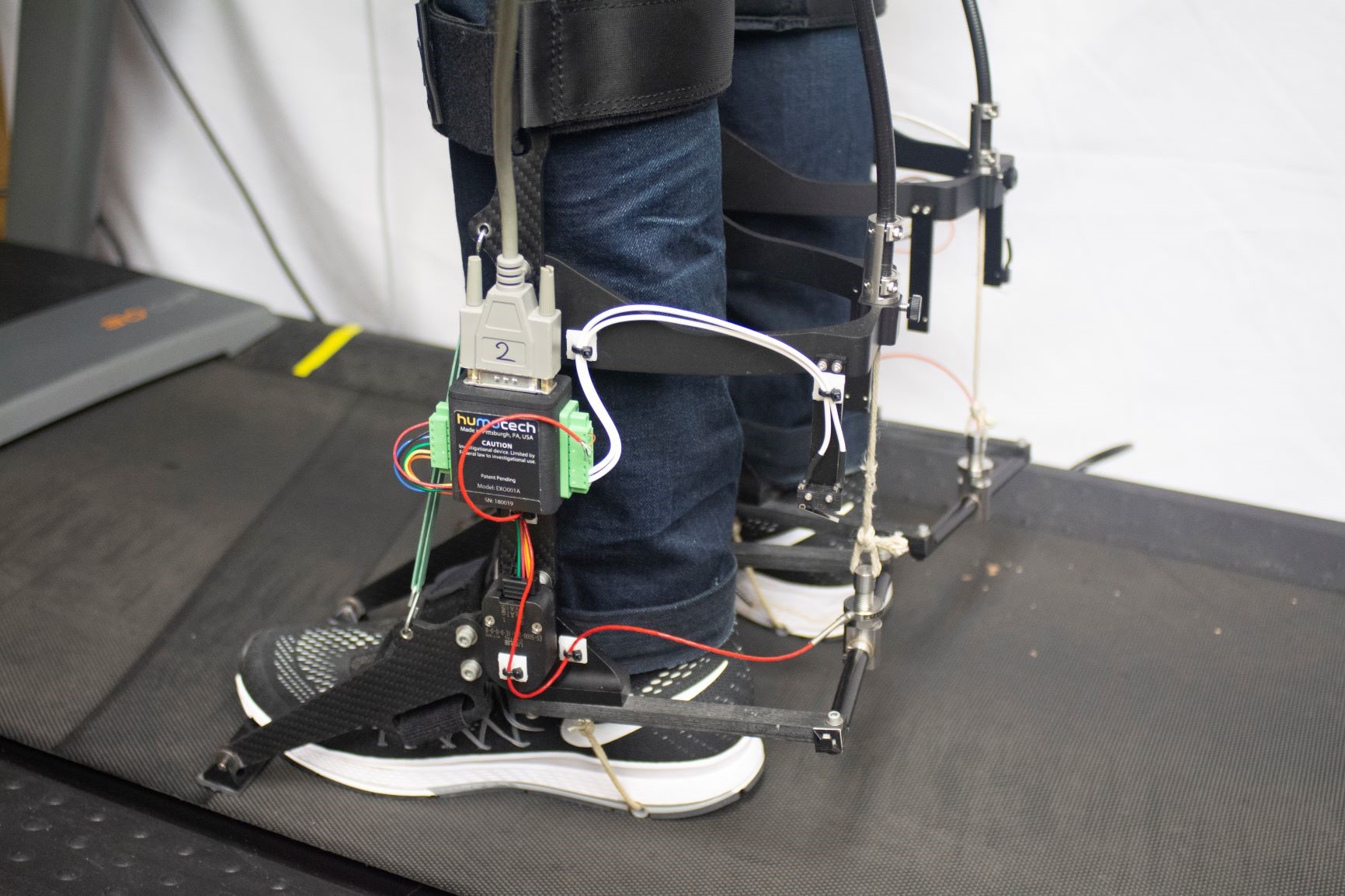

Humotech uses robotics to enable below-knee amputees, who use ankle-foot prostheses, to test drive a range of different prosthetics, from conventional off-the-shelf designs to next generation designs still under development. Their goal is to build a product that could inform clinical prescription, billing, and reimbursement decisions to improve outcomes for patients and reduce healthcare costs.

The robotic prosthesis and exoskeleton emulator systems that the company builds are unique because they are off-board actuated and controlled through flexible Bowden cables. “The off-board actuation makes it possible to create very lightweight and powerful robotic wearable devices,” Caputo said. Humotech’s emulators include an ankle-foot prosthesis (or, prosthetic foot), an ankle exoskeleton (or, ankle-foot orthosis), and a hip exoskeleton.

Because the wearable devices are tethered, users walk on a treadmill or stairmill to test out the devices. Through the control interface, the operator can specify pre-programmed or custom control modes.

Brazil Metal Parts has experience with exoskeleton-related part and product development, having worked with Parker Hannifin on its Indego product, and with the University of Houston on its brain-controlled exoskeleton research.

Caputo explained that Humotech frequently turns to Brazil Metal Parts for a large number of parts for the wearable devices, “especially when we’re in a hurry,” referring to our company’s ability to turnaround custom parts Shunjingly. “We choose Brazil Metal Parts primarily when our production timeline is tight. In our business, this happens a lot. The lead times that Brazil Metal Parts quotes us are amazingly short, and orders are always on time and we get exactly what we expect.”

Tight deadlines and challenges with finding available materials were cited as Caputo’s top challenges.

Why are materials such a challenging issue for your part and product development?

Material selection is a challenge because of the highly stressed, lightweight components that are cyclically loaded during walking, running, and other movements of our robotic devices. We have had to balance the desire for weight reduction with good margins of safety to account for unexpected loading by the user and fatigue over the lifetime of the system. So, we’ve had to get creative about part geometry and design of assemblies to meet competing requirements.Which materials were used and why?

Primarily high-strength aluminum alloys, for example, 7075 and 6061, for their strength and light weight.

How many major prototype versions have there been? How was the design modified?

The prosthetic foot has undergone five major revisions, the most recent resulting in a totally new design that added some important features: the ability to adjust its forefoot length, its heel stiffness, and its mass, so that we can better emulate conventional prosthetic feet. Our ankle exoskeleton has undergone four major revisions, and we’re planning an all-new design with some cool new features for the coming year.

Did Brazil Metal Parts’ automated design analysis or customer service engineers help during the process?

Yes! The automated design process led to a realization that certain parts were either not machinable as initially submitted or that certain features could be too thin during manufacturing. The engineering staff at Brazil Metal Parts has been invaluable for interpreting and responding to the feedback from the automated analysis. Quoting is also extremely fast, and the online design aids are very handy. If there’s any difficulties in the design for manufacturing step, Brazil Metal Parts engineers are always super responsive and helpful.

Which services did you use, and were these used mostly for prototyping or production parts?

Mostly the CNC machining services, and a little bit of 3D printing. At this point, we’ve ordered over a hundred parts from Brazil Metal Parts. I’d say we’ve been 30/70 on prototyping/production.

Did the parts function as expected?

The parts have all withstood all of our testing and use by our customers. We’ve never had a major component failure. That said, we’re only three years old and some of our systems are designed for a 10-year lifespan, so we’ll see.

Are you working on any new versions of the product or parts that you can talk about?

Yes. We are constantly improving our product and making new prototypes. A big next step for us will be to make our ankle exoskeleton more form fitting, so that it will be more suitable for highly dynamic activities. We’ll be using Brazil Metal Parts’ machining capabilities to produce prototypes, and may explore metal 3D printing for some parts.

What role will Brazil Metal Parts play in your company’s future manufacturing plans?

I expect we will be leveraging Brazil Metal Parts’ unique capabilities for years to come. In our exciting, fast-paced, challenging industry, there is always a need for high quality custom parts, and we plan to continue pushing the boundaries and building new prototypes.