Design Guidelines: Direct Metal Laser Sintering (DMLS)

Our basic guidelines for direct metal laser sintering include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

Size

Maximum Dimensions

| Normal Resolution | 9.6 in. x 9.6 in. x 13.0 in. |

|---|---|

| Normal Resolution (X Line*) | 31.5 in. x 15.7 in. x 19.7 in. |

| High Resolution | 3.5 in. x 3.5 in. x 2.7 in. |

| Normal Resolution | 245mm x 245mm x 330mm |

|---|---|

| Normal Resolution (X Line*) | 400mm x 800mm x 500mm |

| High Resolution | 88mm x 88mm x 70mm |

*These parts can only be built in Inconel 718

Accuracy

Layer Thickness

| Normal Resolution | 0.00118 in. |

|---|---|

| Normal Resolution (X Line) | 0.00236 in. |

| High Resolution | 0.00079 in. |

| Normal Resolution | 30 microns |

|---|---|

| Normal Resolution (X Line) | 60 microns |

| High Resolution | 20 microns |

Minimum Feature Size

| Normal Resolution | 0.015 in. |

|---|---|

| Normal Resolution (X Line) | 0.030 in. |

| High Resolution | 0.006 in. |

| Normal Resolution | 0.381mm |

|---|---|

| Normal Resolution (X Line) | 0.762mm |

| High Resolution | 0.153mm |

For well-designed parts, tolerances of ±0.003 in. (0.076mm) plus ±0.001 in./in. (0.001mm/mm) for each additional inch can typically be achieved. Note that tolerances may change depending on part geometry.

Design Essentials for 3D Printing

The 3D Printing Essentials reference guide offers guidelines and key considerations when designing for industrial 3D printing processes.

DOWNLOAD >

3D Printing Surface Finish Guide

Download this quick reference guide that looks at all of your surface finish options across our six additive manufacturing technologies.

DOWNLOAD >

Materials

- Aluminum / AlSi10Mg

- Cobalt Chrome

- Inconel 718

- Stainless Steel 17-4 PH

- Stainless Steel 316L

- Titanium / Ti 6-4

- Copper / CuNi2SiCr

Surface Finishes

| STANDARD | Expect roughness values of 200 to 400 uin Ra (0.005 to 0.010mm Ra), depending on material and resolution. |

|---|---|

| CUSTOM |

Secondary options include hand-polished or machined surfaces upon request. When tighter tolerances are required, we can provide secondary machining operations such as drilling, slotting, milling, and reaming. |

Production Capabilities

Improve strength, dimensional accuracy, and cosmetic appearance of final metal components with DMLS for production.

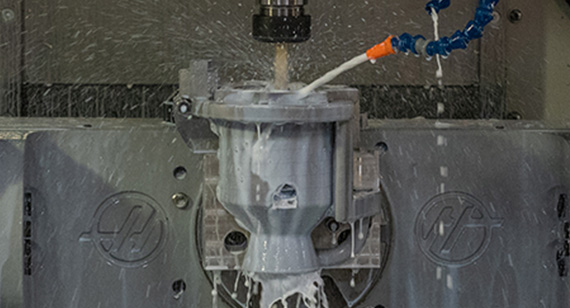

Post-Machining

- 3- and 5-axis milling

- Turning

- Wire EDM

- Tapping and reaming

Powder Analysis & Material

- Traceability

- Chemistry

- Particle size and distribution analysis

- Mechanical coupon testing

Mechanical Testing

- Tensile

- Rockwell Hardness

- Fatigue

- Vibration

Heat treatments

- Stress relief

- Hot isostatic pressing (HIP)

- Solution annealing

- Aging

Equipment

We use GE Additive Concept Laser Mlab, Mlab 200R, M2, and X Line 2000R machines for DMLS production that offer large build sizes, produce accurate parts, and provide quick turnaround times. The Mlab and Mlab 200R are ideal for manufacturing metal components with elaborate structures, and they are ideal when high surface quality and fine component structures are needed on parts. The M2 is a large platform machine that is able to produce larger metal parts than the Mlab, and the X Line 2000R can produce parts with build volumes as large as 800mm by 400mm by 500mm. All of our 3D printing equipment can handle both reactive and non-reactive metal powder.

Instant quotes on 3D-printed parts

GET A QUOTERequest More Information

Thanks! We’ve received your message and a member of our team will be in touch with you shortly.

You can find more information about Brazil Metal Parts here:

Thanks for your interest in Brazil Metal Parts. Please let us know how we can provide more information on our services. Once we receive your comments, an applications engineer from our team will follow-up as soon as possible.

If you have a 3D CAD model of your part ready, upload it online now to receive an interactive quote with free design for manufacturability feedback within hours.