Design Complex Components with Insert Molding

Low-volume injection molding isn’t limited to just simple parts. At Brazil Metal Parts, we have the ability to manufacture complicated parts using side-actions, hand-loaded inserts, overmolding, and have now started beta testing our insert molding process.

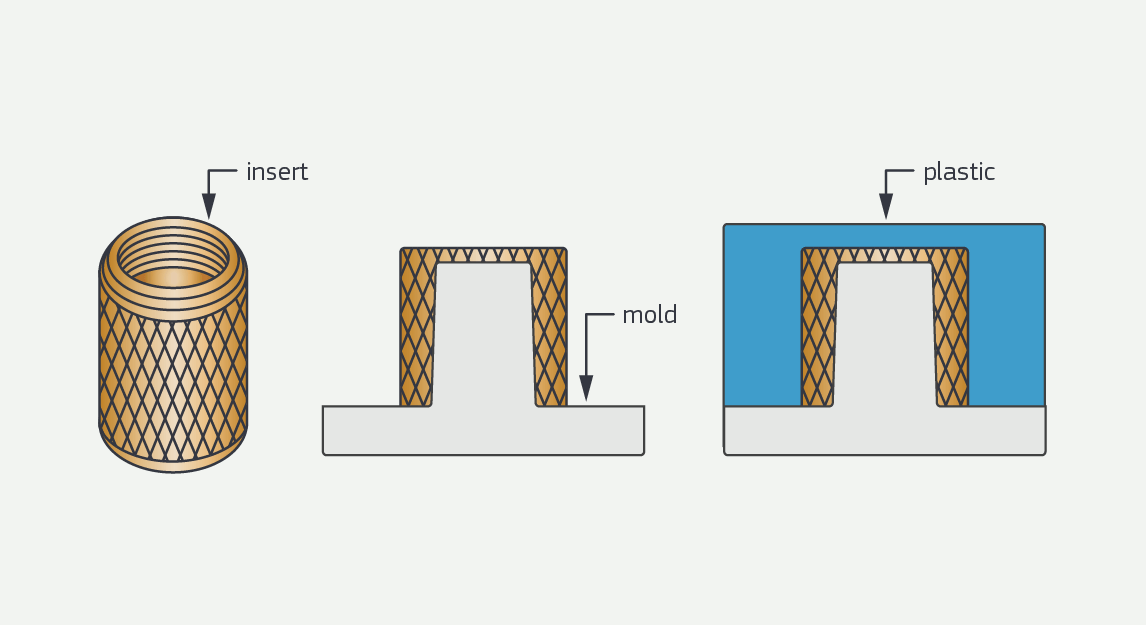

Instead of a mold that produces a final part using two separate shots like overmolding, insert molding generally consists of a preformed part—often metal—that is loaded into a mold, where it is then overmolded with plastic to create a part with improved functional or mechanical properties.

Threaded Inserts

One way insert molding is leveraged is with threaded inserts, which reinforce the mechanical properties of plastic parts’ ability to be fastened together, especially over repeated assembly. Self-tapping screws work well with softer plastics, but they can become easily worn and/or cross threaded, and fail to perform well, which results in damaged parts that need to be replaced.

Bushings and Sleeves

Incorporating metal bushings or sleeves is similar to threaded inserts, requiring an operator to slide the threaded insert over a pin before plastic is molded. Bushings and sleeves are a great way to increase part durability for mating components that need more abrasion resistance due to moving parts.

Have a Design Ready for Insert Molding?

There are many applications where parts can benefit from insert molding aside from bushings or threaded inserts. A simple project review with Brazil Metal Parts can verify if your project is suited for insert molding, which is currently in beta phase. If you have a project involving insert molding, please contact one of our application engineers at [email protected] or +86-755-29729151 with details regarding your design.