We know the importance of having an optimized part design before any actual production begins, which is why we provide automated design for manufacturability (DFM) analysis within hours on every part that is uploaded.

What is DFM?

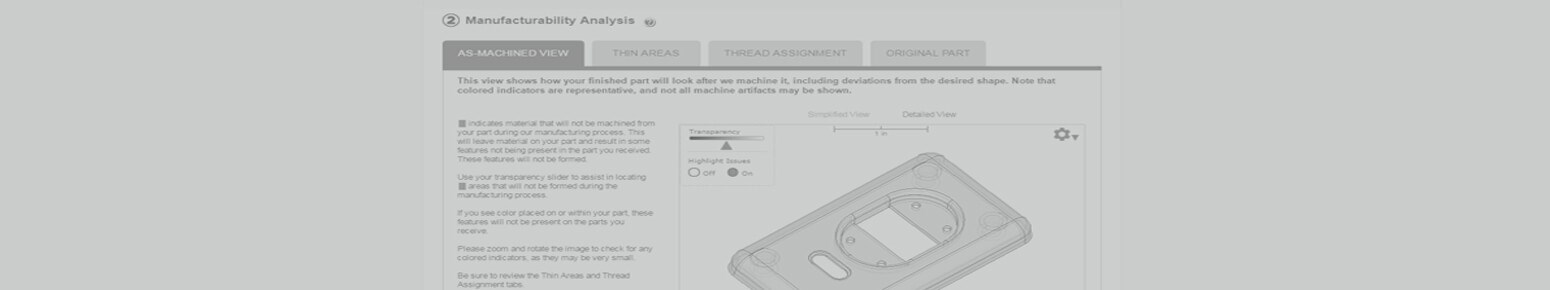

DFM analysis helps to ensure you get quality parts without production delays. You’re able to access an interactive 3D model of your part online, which allows you to review its geometry and assess any potential manufacturability issues that are highlighted. Design considerations with suggested modifications may include:

- Undercuts

- Draft

- Surface finishes

- Wall thickness

- Material flow

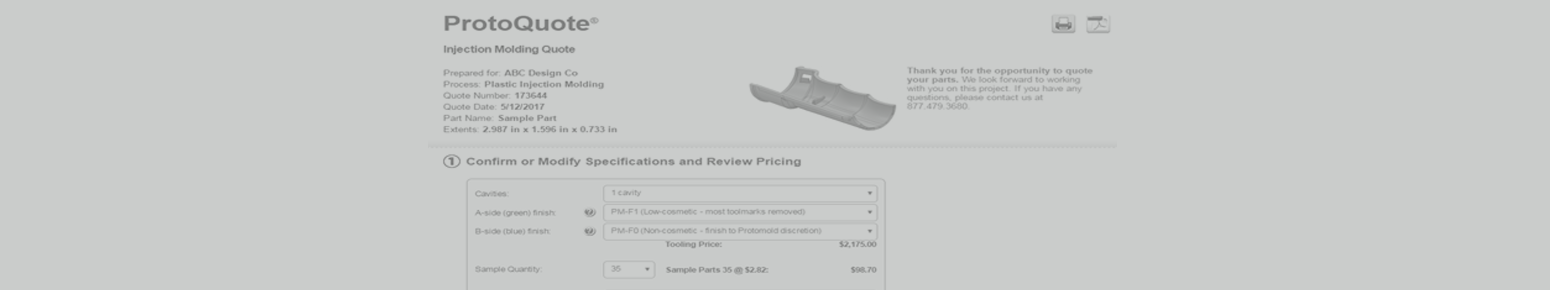

Making important design adjustments to part geometry before manufacturing begins saves you time and money, and ultimately increases your product’s speed to market. Read our design tip to learn more about ProtoQuote.

Navigating ProtoQuote

Explore Sample Quotes

To get a good idea of how ProtoQuote works, check out our sample quotes for machining and molding. You can make adjustments to things like materials, turnaround time, and surface finish, and manipulate a 3D CAD model to see how DFM is integrated.

“Brazil Metal Parts’ quick-turn manufacturing services coupled with automated quoting and design analysis enable our iterative design and development process to meet tight deadlines with reduced design risk.”