Post-Processing for 3D Printing

Choose from 3D printing finishing options that strengthen parts, improve cosmetic appearance, and other benefits.

Clear coating is available and commonly applied to parts to create a clear cosmetic finish. Painting is also possible on 3D-printed parts. Some sanding and polishing will be needed to make the surface smooth, after which the part can be masked off and painted with whatever colors you like—just send the Pantone numbers with your design upload, together with a CAD model indicating which color goes where. The parts are sprayed with an automotive-grade paint. Soft-touch painting is also available.

Plating on 3D-printed parts increases strength and durability of plastic parts. Electroless nickel plating is a great way to mimic a cast aluminum or magnesium part for light-weighting purposes.

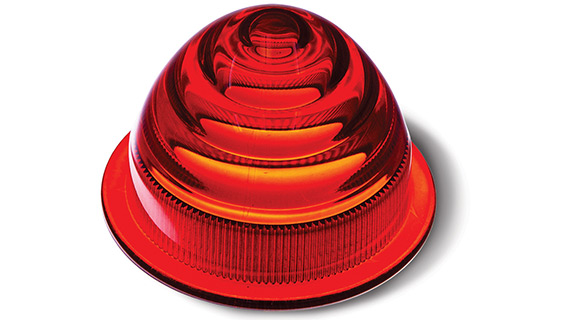

Dyeing of stereolithography (SLA), selective laser sintering (SLS), Multi Jet Fusion (MJF), and PolyJet parts is possible at Brazil Metal Parts. SLA parts can be dyed black, green, red, blue, or yellow. The finished parts are simply bathed in hot dye for a short while for a consistent color. This option is one of the fastest, lowest-cost ways to make printed parts cosmetically appealing. There’s no chance of masking off certain areas like there is with painting, but for SLA, SLS, MJF, and PolyJet parts, especially those made of translucent acrylic or polycarbonate-like materials, this is often an excellent option.

Decaling provides a great way to attach company logos, safety warnings, and other graphic to increase cosmetics or functionality. We don't supply these products, but can apply them for you. Note that adhesive and thermal-transfer decals won’t stick to the rough surface typical of some 3D-printed parts, making sanding or otherwise smoothing of the target surface a prerequisite to decal application.

Texturing improves the finish of 3D-printed parts by making them less slippery, improves ergonomics, and enhances cosmetic appearance. When prototyping 3D-printed parts that will later be injection molded, it’s possible to apply a spray texture to mimic a Mold-Tech brand-like finish used in many mold cavities. This same technique can be used to apply a soft-touch paint or urethane clear coat to a 3D-printed part, a process that also improves weather and sun resistance on the UV-curable materials used with SLA.

Polishing is possible on 3D-printed parts to create a high-quality finish. Again, some level of smoothing is needed to apply paint and decals, but highly cosmetic surfaces can be taken even further. If this is a requirement, you'll need to identify your finish expectations on your part with a drawing or screenshot.

Heat treating metal parts build with direct metal laser sintering (DMLS) eliminates heat-induced stress and potential warping. It's also used to harden DMLS metals, strengthen them, make them less prone to cracking and fatigue, or make them more pliable. If you’re looking for an extremely tough and hardened 3D-printed metal, stainless steel 17-4 PH is a solid option.

Secondary machining is possible on DMLS parts if a highly accurate, smooth surface is specified. Other high-requirement operations for DMLS include boring or reaming close tolerance holes or tapping of those that require threads. And depending on the material, inserts of various kinds can be heat-staked or glued into place.