Selective Laser Sintering (SLS)

Selective laser sintering (SLS) is an industrial 3D printing process that produces accurate prototypes and functional production parts in as fast as 1 day. Multiple nylon-based materials and a thermoplastic polyurethane (TPU) are available, which create highly durable final parts that require heat resistance, chemical resistance, flexibility, or dimensional stability. With SLS 3D printing, no support structures are required making it easy to nest multiple parts into a single build and an economical solution for when higher volumes of 3D-printed parts are required.

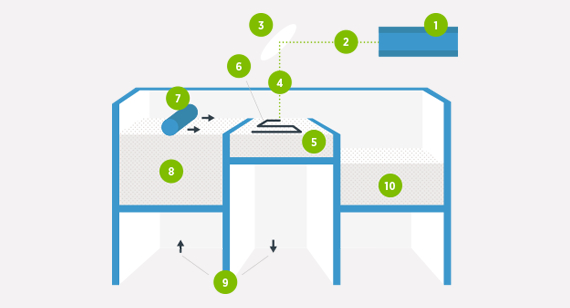

How Does SLS 3D Printing Work?

The SLS machine begins sintering each layer of part geometry into a heated bed of nylon-based powder. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. The process is repeated layer by layer until the build is complete.

When the build finishes, the entire powder bed with the encapsulated parts is moved into a breakout station, where it is raised up, and parts are broken out of the bed. An initial brushing is manually administered to remove a majority of loose powder. Parts are then bead blasted to remove any of the remaining residual powder before ultimately reaching the finishing department.

- 1 to 50+ parts

- Shipped in as fast as 1 day

- ISO 9001 and AS9100D Certified

- jigs and fixtures

- housings

- snap fits and living hinges

Watch: Why Use SLS?

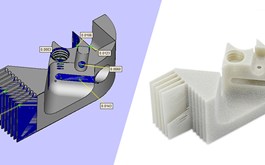

See how SLS uses actual thermoplastic and elastomeric materials to produce parts with good mechanical properties. Final parts can be used to test future injection molding designs or as functional, end-use components.

Material Options with SLS

Four different types of nylon materials are available in SLS for different levels of stiffness and flexiiblity.

Maximum Dimensions

| PA12 | 19 in. x 19 in. x 17 in. |

|---|---|

| PA11, PA12-GF, PA12-MF, PP, TPU-70A | 10.6 in. x 12.6 in. x 16 in. |

| PA12 | 482mm x 482mm x 431mm |

|---|---|

| PA11, PA12-GF, PA12-MF, PP, TPU-70A | 269mm x 304mm x 406mm |

SLS Tolerances and Accuracy

| Layer Thickness | 0.004 in. |

|---|---|

| Minimum Feature Size | 0.030 in. |

| Layer Thickness | 0.1016mm |

|---|---|

| Minimum Feature Size | 0.762mm |

Tolerances: For well-designed parts, tolerances of ±0.010 in. (0.25mm) plus ±0.0015 in./in. (0.0015mm/mm) for each additional inch can typically be achieved. Note that tolerances may change depending on part geometry.

Surface Finish and Post-Processing Options

| STANDARD | Bead blast to remove all powder, which leaves a consistent overall texture. |

|---|---|

| CUSTOM |

Secondary options include a primer or dye color that can be applied as well as taps and inserts. |

Selective Laser Sintering (SLS) Materials

| Material | Description | Key Benefits |

|---|---|---|

|

PA12 White |

PA 12 White is an economical material choice for functional prototypes and end-use parts. It offers high impact and temperature resistance, is very durable, and remains stable under a range of environmental conditions. The nylon material exhibits a white finish with a slightly rougher surface texture compared to other nylons. |

|

|

PA11 Black |

PA 11 Black provides excellent ductility and temperature resistance without sacrificing tensile strength. It offers one of the highest elongation break thresholds in the nylon family. |

|

|

PA12 Mineral-filled |

PA12 Mineral-filled is a 25% mineral-filled nylon that offers the highest stiffness among Brazil Metal Parts’ selective laser sintering materials. It’s an excellent choice when stiffness and high temperature resistance are the most important requirements. |

|

|

Polypropylene Natural |

This material is ideal for prototyping and end use production. PP Natural is a low weight material, by comparison to other plastics, and it exhibits durability in addition to being both tough and flexible. |

|

|

PA12 40% Glass-filled |

PA 12 40% Glass-Filled is a polyamide powder loaded with glass spheres that add stiffness and dimensional stability. The material possesses higher thermal resistance than unfilled polyamides and exhibits excellent long-term wear resistance. Due to the glass additive, it has decreased impact and tensile strengths compared to other nylons. |

|

|

TPU-70A |

TPU-70A combines rubber-like elasticity and elongation with good abrasion and impact resistance. It can be leveraged to produce both prototypes and functional parts. |

|

Equipment

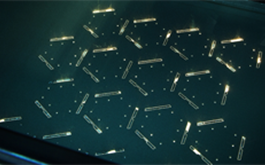

Our SLS equipment includes sPro140 machines, which have the world’s largest sintering build volume, and feature fully digital high-speed scanning systems, unparalleled process consistency, and closed systems for powder blending and delivery for reliable part quality. We also use sPro60 machines, which allow for multiple materials and high throughput.

Design Essentials for 3D Printing

The 3D Printing Essentials reference guide offers guidelines and key considerations when designing for industrial 3D printing processes.

DOWNLOAD >

3D Printing Surface Finish Guide

Download this quick reference guide that looks at all of your surface finish options across our six additive manufacturing technologies.

DOWNLOAD >

Tour Our 3D Printing Facility

Take a quick tour through our additive manufacturing facility in North Carolina, one of the largest 3D printing operations in the world, to see how we build high-quality prototypes and fully functional end-use components and assemblies.

Resources

How to Design for Nylon 3D Printing

Accelerate Continuous Improvement with 3D Printing

3D Printing Materials: Select the Right Plastic or Metal for Your 3D-Printed Part

6 Ways to Cut Costs, Improve Designs with Industrial 3D Printing