Design Tips

Get quick advice on creating plastic, metal, and elastomeric parts for 3D printing, CNC machining, sheet metal fabrication, and injection molding. Designing with manufacturability in mind can accelerate production time and reduce production costs.

Manufacturing Tool Kit for the Aerospace Industry

Injection Molding

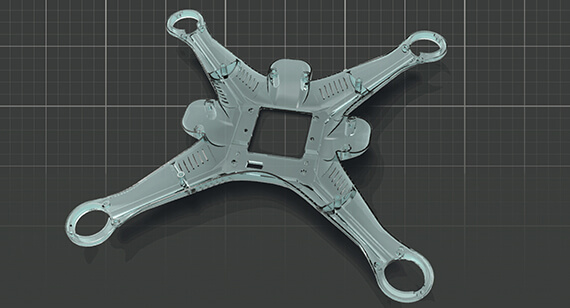

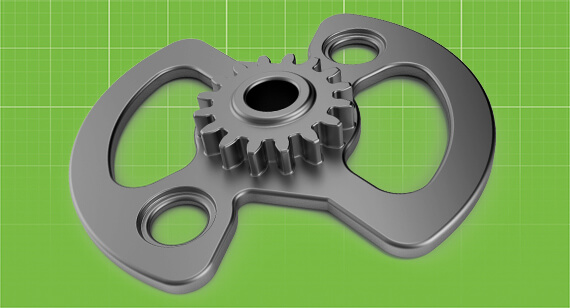

3D Printing

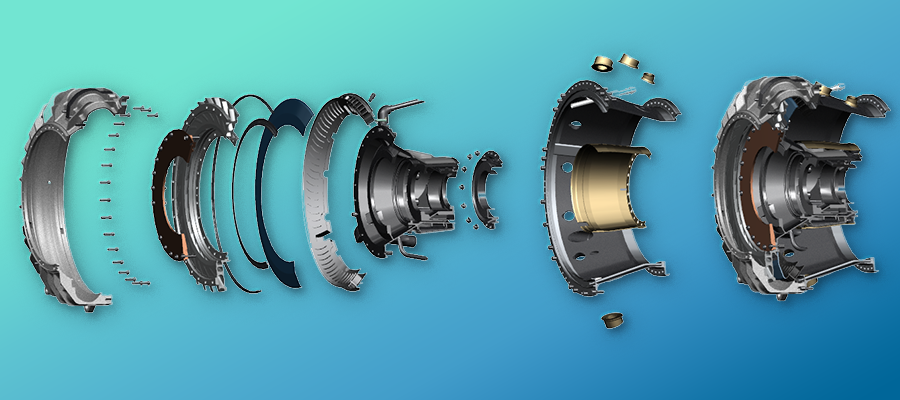

Post-Processing for Metal 3D Printing

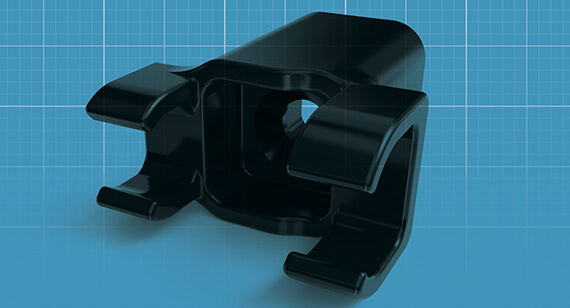

Designing for Jigs and Fixtures

Designing for Nylon 3D Printing

Designing for Direct Metal Laser Sintering

Redefining Design with Metal 3D Printing

Designing for Multi Jet Fusion

Designing for Selective Laser Sintering

Designing for Stereolithography

3D Printing for Production Parts

How Draft Keeps Your Drink Cold

When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the part is critical to improving the moldability of your part. Without it, parts run the risk of poor cosmetic finishes, and may bend, break or warp due to molding stresses caused by the plastic cooling.

Talking Cosmetic Defect Blues

Identifying potential cosmetic flaws like sink, knit lines, flash, blush and other issues early in the injection molding design process not only improves the appearance of your parts, but their overall moldability too.

Design Essentials

We've compiled our most essential manufacturing tips into three downloadable design guides on 3D printing, machining, and molding. Each looks at improving manufacturability, reducing production costs through design, material selection, and more.

3D Printing

CNC Machining

Injection Molding