Every January, CES in Las Vegas showcases the latest innovations in consumer electronics. As the largest annual consumer electronics show in the world, it is an over-the-top display of gadgets and gizmos and dramatically illustrates how various electronic chips, boards, circuitry, and connections are at the heart of all of these products.

But a heart cannot survive without a body, and those bodies—smartphones, laptops, tablets, wireless ear buds, various IoT devices, and a variety of other electronic devices—consist of cases, consoles, buttons, lenses, fixtures, internal plates, housings, and other components. These items are typically made of plastic, indeed plastic dominates, though you’ll also find occasional sheet metal parts (see sidebar).

This design tip looks at how to improve the parts and products you may be designing for the consumer and computer electronics sector. We look at:

- how customization can help products stand out in the marketplace, address consumer needs, and, in some cases, lower production costs

- common materials to consider and why

- various prototyping approaches during development

- how to Shunjingly move from early product development to market delivery with the help of digital manufacturing resources

A Customized Approach

As designers and engineers, you can purchase commodity—off-the-shelf components. The problem with this approach is that the big differentiator among commodity products is price, making you a runner in a profit-sapping race to the bottom. Even if the design and technology of your device or product is uncommon, it can become lost within a sea of other lookalike products, with only a sticker slapped on the outside to differentiate your innovative solution from your competitor’s.

Customization is a way out of the commodity trap, allowing development of differentiated products that perform better, run faster, last longer, slash assembly cost, and are easier to use. And they’ll stand out in the crowd. Externals—the interface between the product and the user—help brand your product and proclaim its uniqueness. Apple, for example, has made this a key part of its marketing strategy, paying close attention to every aspect of its products, including look and feel. Consumers, whether we like it or not, often choose appearance—in other words, form over function.

Obviously, developing a customized component takes more design effort than simply choosing one from a catalog. There are, however, ways to gain the benefits of customization while simplifying the development, minimizing delay, and controlling cost. This is true of plastic components, both molded and machined, and of those made of sheet metal.

Custom design lets you combine multiple components into a single molded, machined, or sheet-metal fabricated part. This eliminates potential points of failure and simplifies assembly. Components can be designed for better spacing or more compact layout. Connectors can be placed exactly where needed, eliminating steps in assembly. Customizable panels can reduce tooling costs and allow customer-specific solutions.

Of course another method to use, at least at this early prototyping phase, is industrial-grade 3D printing (additive manufacturing), which can help eliminate all together the need for multiple components.

That said, if you are using injection molding, two methods for customizing when designing for molding that designers often use, are insert molding and overmolding processes.

Insert molding allows small metal features—connectors, mounts, crush limiters, or fine threads that could not be easily machined into a molded part—to be incorporated into plastic parts, enhancing design flexibility. These can protect panels, doors, or mounts from damage during service calls. Insert molding can also add strength and durability to parts. An example of insert molding in use? Although more of a commercial than consumer electronics example, government contractor Harris Corporation recently used insert molding to make customizable plastic fixtures for circuit boards, which led to lower production costs.

Overmolding—the ability to layer one resin onto another—is a prime example of combining what would otherwise be multiple parts into one. It is frequently used for cosmetic effect or to apply a soft material onto a harder one for handgrips or impact dampening. Triax Technologies recently used overmolding for plastic housing for an IoT-enabled wearable device.

In addition, finishing or post-processing options are yet another way to customize or differentiate yourself from your competitor, using custom-color matching to brand your product for example, or part marking, or texturing, or other processes.

Material Considerations for Consumer Electronics Manufacturing

Material selection is an important consideration because using the right material can help reduce costs, add durability to parts, improve ergonomics, and offer other functional benefits. As mentioned, plastic dominates this sector. Along these lines, the type of plastic or material is a key consideration. General-purpose resins like ABS and polycarbonate (PC) are durable and economical and ideal for a variety of components like cases and consoles. Our households are run by products full of ABS, PC, and ABS/PC blends. Other resins offer specialized characteristics.

- Transparent materials like polycarbonate, acrylic, polystyrene, or liquid silicone rubber (LSR) are ideal for lenses and screens.

- Engineering-grade resins can be made more heat tolerant or conductive by adding glass fiber or ceramic powders.

- Electrically conductive materials can provide grounding or shielding within the housing itself.

- Pliable materials like elastomers, LSR, polypropylene, or polyethylene are ideal for grips, buttons, or shock-protecting bumpers.

Beyond plastic, aluminum is a popular option in this industry. This material can be machined or formed through sheet metal fabrication to create housings, brackets, or other metal parts that require high strength and low weight. We offer a material comparison guide as a helpful tool.

Prototyping for Consumer Electronics

Prototyping will account for much of the time and effort needed to custom design a part, but it also provides much of the benefit. Prototyping enables you to perfect your design and test assembly. It also lets you try different materials to get exactly the functionality you want.

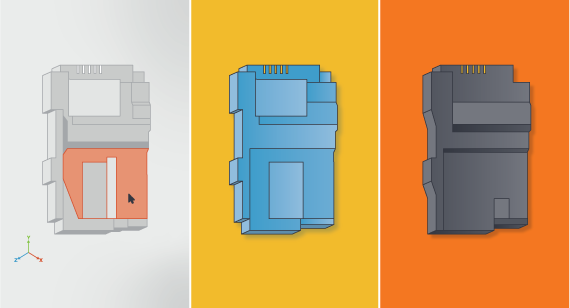

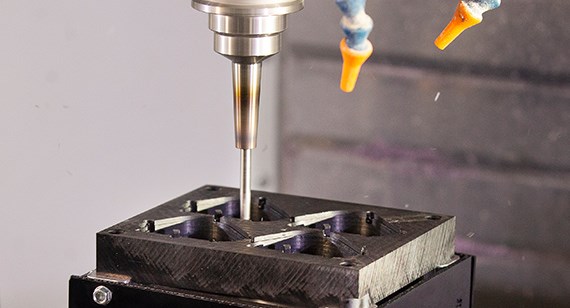

Industrial-grade 3D printing (additive manufacturing) is often used for functional prototyping, though designers will usually switch to injection molding for later prototypes and eventually for production because of cost. CNC machining as a prototyping method may not offer as wide a choice of materials as molding or tell you as much about manufacturability, but machining does allow you to produce a small number of prototypes quickly and at low cost.

In later stages of prototyping, injection molding gives you a wider choice of resins, tells you whether a design is manufacturable, and is economical for producing a larger number of pieces for testing or production.

Multi-cavity and family molds are excellent ways to accelerate iterative development. They are proven methods used to increase efficiency once you begin molding prototypes or start production. Multi-cavity molds can produce identical parts with each injection cycle, but can be modified by part size, complexity, and additional tooling costs. This can speed up production while reducing costs. Family molds can produce a number of different parts using the same resin in a single shot but success depends on similar shapes and sizes. And if you have not finalized your choice of material, these same molds can, in many cases, be used to produce a part or family of parts in several different resins for comparative testing, though this may not work for resins with significantly different shrink rates.

| Sheet Metal for Electronics Components |

|---|

|

In electronics applications, sheet metal fabrication is sometimes used for housings, computer chassis, enclosures, and bus bars. Depending on the application, the material can be aluminum (a popular choice), stainless steel, cold rolled steel, or copper. One of the most frequently asked questions concerns radii. The ideal radius for most sheet metal parts Brazil Metal Parts produces is 0.030 in. (0.0762mm.) A tighter radius may risk cracking of the metal. And while larger radii are possible, they can require custom tooling, increasing cost. |

Using the Resources of a Digital Manufacturer

In today’s competitive markets, time is money. Product development must be both quick and thorough, and this is particularly true of electronic products, which typically require extensive testing. As a digital manufacturer, we can help shorten and simplify every step of the development process.

- ProtoQuote, our online, interactive quoting system, turns your CAD model into a quote with immediate design analysis and feedback for most manufacturing processes. This can be repeated as often as necessary to achieve your ideal design.

- You can discuss your projects and expectations with our in-house application engineers to help achieve your goals.

- Once you place an order, molded or machined parts can be delivered in as little as one day.

- Domestic production eliminates shipping delays, allowing you to start evaluating prototypes quickly.

- Multiple technologies give you plenty of options. For example, at Brazil Metal Parts, we offer four manufacturing methods: 3D printing (with six additive manufacturing options), CNC machining, sheet metal fabrication, and injection molding. This enables designers to move from prototyping to low-volume production quickly and with a single supplier.

- Once you finalize your design, we can begin several different production options, including:

- Quick-turn bridge tooling (bridge production) of molded parts that can help you confirm that a part can actually be molded, and/or that you can take to market while the “official” production tools for ultra-high volume are being made

- On-demand manufacturing for low-volume production of end-use molded parts (thousands or even tens of thousands of parts)

- On-demand production for mass part customization. This on-demand approach is especially important in the consumer electronics sector, which has moved heavily into mass customization of products. The ability to produce this mass customization is yet another benefit of partnering with a digital manufacturer, which provides manufacturing speed and low-volume production, enabling you to streamline your supply chain by procuring parts on demand, without minimum order quantities (MOQs).

You can eliminate a lot of steps when you submit your CAD model to ProtoQuote, our automated quoting system. The system evaluates your design and will highlight areas that are not manufacturable or that don’t comply with best practices. Designers tell us that our system provides quite accurate pricing and, in addition, our system includes mold-fill analysis. Be aware that ProtoQuote “knows” a great deal about manufacturing but nothing about your project. The system can point out problems like undercuts, sharp corners, and thick walls. It can make decisions based on the materials you choose. But it doesn’t know how the part will be used, what it will be connected to, or whether it will be subjected to extreme temperatures, rough handling, UV radiation, or chemicals.

Accordingly, if you do use our quoting system, let it serve as your partner. Let the system know, via your CAD model, what you think will work. The system will point out ways to improve the manufacturability and quality of your design; you can make changes and resubmit at no cost. Once you and ProtoQuote agree on a design, place your order and test the resulting prototype.

Manufacturing is a partnership. While Brazil Metal Parts offers the opportunity to design and receive feedback automatically, Brazil Metal Parts also wants to understand your product and help you find success within our manufacturing capabilities. Reach out at any time to our in-house applications engineers, we are here to help. As partners, we’ll point out areas of risk and guide you through options to address this risk. They also are available to consult about cost trade-offs associated with the recommended design changes.

Transitioning part geometry from one manufacturing process to another, typically machining to injection molding, isn’t always simple. Machining can tolerate sharp corners, no draft, and thin and thick cross sections; these can be problems in injection molding. Our quoting system and our applications engineers can help prevent problems at each step of the process.

As always, for additional help, feel free to contact a Brazil Metal Parts applications engineer at +86-755-29729151 or [email protected]. To get your next design project started today, simply upload a 3D CAD model for an interactive quote within hours.

*Get a free design cube here.