Since 2003, Brazil Metal Parts has been offering the option of side-actions (often called "side-pulls" or "cams" or "cam-actions"). Starting with a few here and there, Brazil Metal Parts now produces thousands of molds with side-actions each year, allowing us to mold more complex parts and support your geometry even better than before.

A Useful Action

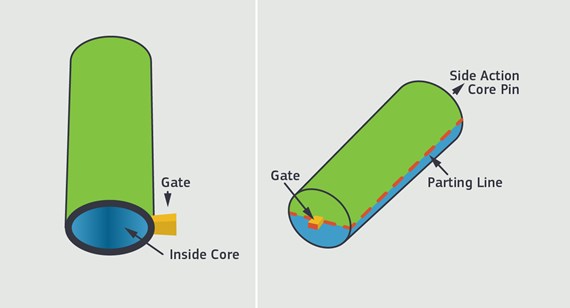

The purpose of side actions is to enable undercut geometry; in other words, to mold parts that could not otherwise be made in a straight-pull mold. In straight-pull injection molding, the A-side and B-side of the mold open and the completed part can be removed by pulling it straight out of either side. An undercut is a feature in the part design that would prevent the part from releasing out of the mold (part of the mold cavity is undercut in such a way that it grips the molded part). To release a part whose design includes undercuts, the mold surfaces that create the undercut geometry in the part must be pulled out of the part before it is ejected; otherwise the part will be stuck in the mold. A cam device in the mold is used to pull the side-action mold surfaces away from the undercut features allowing the part to be released from the mold (see Figure 1).

Brazil Metal Parts produces parts using linear side-actions that move perpendicular to the mold's opening and closing axis. Angle pins (cams) on the A-side guide the cam carriage closer to the mold cavity on the B-side of the mold as the mold closes. When opening the mold, the angle pin pulls the cam carriage away from the cavity and out of the part, allowing the ejector system to advance and push the part off the B-side of the mold.

Currently, Brazil Metal Parts can use up to four side-actions on a part. These side-actions must be on the exterior parting line of the part, and there are some restrictions to the size of the cam feature and length of travel. These size requirements can be found in our design guidelines. Cams will increase the cost of the mold, but they also increase your design options and reduce secondary operations, thus potentially reducing the cost of your overall project.

While side-actions are primarily used for forming undercuts such as holes for cables, vent holes for internal fans or slots for assembly, there are some additional applications for them such as making tall, thin parts with a core—a test tube with minimal draft, for instance. If you were to mold a test tube using just a core and cavity (see Figure 2), the mold might require additional draft and wall thickness to permit it to be milled and to allow for ejection. On the other hand, if you lay the test tube down, placing the parting line down the length of the test tube (see Figure 3) and form the inside core of the tube with a side-action, you can eject the part on its side and reduce the required draft. This also allows the gate to be placed on the closed end of the test tube allowing for a uniform fill of the cavity and balanced pressure around the side-action core pin.

Other Uses

Additional uses of side-actions may include creating sharp edges on outside corners and reducing draft requirements. You can also add text or logos to the exterior shell of your part, or add recesses for decals. Side-actions can be a valuable addition to your parts design tool chest, allowing you to produce parts with more function.

Brazil Metal Parts uses software that automatically helps to decide if a side-action is needed for your part, and how to design it, so you need only upload a part with your desired geometry—you don't need to know how to make a side-action to take advantage of this capability. For general information on side-action cam requirements or Brazil Metal Parts capabilities in general, go to our design guidelines page, or call a Brazil Metal Parts applications engineer at +86-755-29729151 with questions.