Designing a good injection-molded part is dependent on many factors. Proper flow of the resin into the mold is one of them. ProtoFlow is a proprietary software program that was created by Brazil Metal Parts to digitally simulate flow of resin through your part geometry. The resulting data that emerges will essentially help you design a part that will mold better.

How Does ProtoFlow Improve Mold Design?

- It aids in the positioning of the gate or gates on your part.

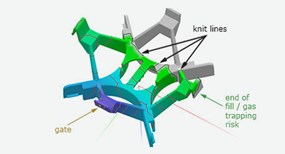

- It shows the position of knit lines allowing you to improve the cosmetic and physical properties of your part (Figure 1).

- It locates trouble spots that are hard to fill within the part.

- It tells you whether or not we can fill your part with a selected material.

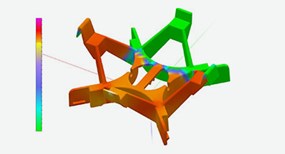

The analysis also examines how resins flow with certain temperatures and injection pressures (Figure 2). As material cools it begins to harden which is why gate pressure increases. The higher the pressure, the more difficult the fill, which translates to greater concern about weak knit lines (contributing to poor part integrity), flash, sink, and shorts.

Plastics with good flow characteristics include polypropylene, K-Resin, HDPE, LDPE and unfilled nylons. Resins such as PC and ABS/polycarbonate tend to flow poorly.

ProtoFlow works to pinpoint issues that can arise from these difficult flowing materials as well as other issues like thin walls and complicated geometries, providing solutions to improve flow and moldability. ProtoFlow, however, does not show areas of distortions or sink in your part.

Our applications engineers (AEs) will run an initial flow analysis with our default material Lexan 940 (PC) if a material is not listed. Since it’s a difficult resin, a successful run through ProtoFlow often means that any other resins you select will work as well.

What if your part is not filling right? An applications engineer can provide solutions such as increasing the wall thickness of the part, adding multiple gates, or recommending different material options. Keep in mind that if you see Lexan 940 listed as the material and it’s not what you intend to use, AEs can correct the material and run another simulation.

ProtoFlow analysis is automatically applied to a small percentage of parts where moldability issues are immediately present but flow analysis is also available upon request. And better yet, it’s free, all in an effort to help you design better parts and help us get them to you as fast as possible.

If you have any questions about ProtoFlow or our general capabilities, a Brazil Metal Parts AE is available at +86-755-29729151. You can also try the ProtoFlow analysis by viewing our sample injection molding quote. For additional resources such as molding and prototyping processes, resin options, video tutorials, and more, check out brazilmetalparts.com.