Design Aids

Learn about the design elements, materials, and surface finishes of injection-molded parts by registering for our free design aids.

One of the best ways to learn about our injection molding process is to have an actual plastic part in your hands to explore. That’s why we created the Design Cube, which shows part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding.

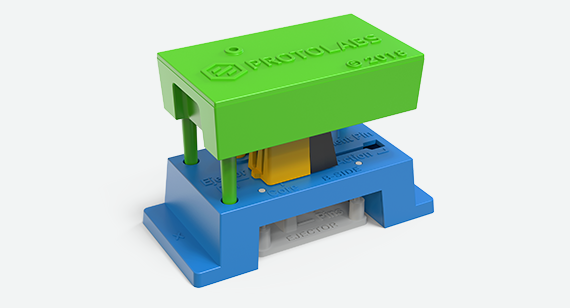

This design aid shows the mechanics of how the A-side and B-side of a tool work together during the injection molding process to create plastic parts. The Demo Mold demonstrates the functionality of side-actions, sprues and runners, ejector pins and plates, and the relationship between core and cavity. It helps those new to injection molding easily visualize the process and is a great teaching device for educators.

*Shipment of design aids are strictly for fulfillment within the US.

*Shipment of design aids are strictly for fulfillment within the US.

Dummies Books

Our Dummies books look at the digital manufacturing tools available to today's product designers and engineers. Read about various 3D printing, machining, and molding technologies, material options, tips for part design, and how digital manufacturing is being used for commercial applications in nearly every industry.

Injection Molding for Dummies

Industrial 3D Printing for Dummies

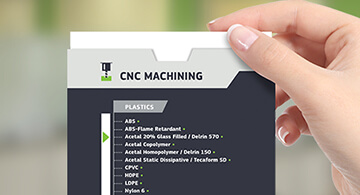

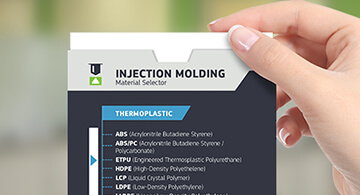

Material Selectors

These pocket-sized Material Selectors are quick reference guides to help you identify the right plastic and metal materials for your next project. It lists specific measurements on properties to ensure you have the most suitable material and process for your part’s application.