Injection molding can provide a range of lifetime part volumes—from as few as 10 to more than 10 million. We're a low-volume manufacturer, typically producing 10 to 10,000+ parts from aluminum molds. We provide two injection molding service options. One is best suited for those who need smaller part quantities often associated with prototyping and the other a good fit for those who require larger part quantities common in low-volume production.

25 parts to 10,000+ parts

Shipped in 1 to 15 days

Prototyping or On-demand Manufacturing?

While the molds themselves are similar, part quantities, lifetime maintenance, quality documentation, and pricing vary depending on which service option is chosen. The right one depends on your project needs.

| PROTOTYPING | ON-DEMAND MANUFACTURING | |

|---|---|---|

| OBJECTIVE | I need to validate my design | I need the flexibility of on-demand production of end-use parts |

| BEST WHEN |

|

|

| MOLD PRICE | Lower | Higher |

| PART PRICE | Higher | Lower |

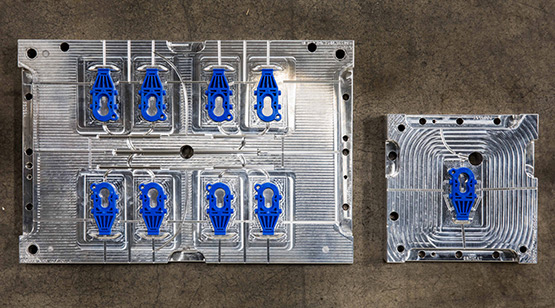

| MOLD CAVITIES | Single | Single and multi-cavity |

| GUARANTEED MOLD LIFE | Limited (guaranteed for at least 2,000 shots) | Unlimited |

| MOLD STORAGE | Stored for 18 months of inactivity | Stored for 3 years of inactivity |

| MOLD OWNERSHIP | Upon request | Yes |

| QUALITY DOCUMENTATION | Basic inspection reports available upon request | Basic inspection reports included; enhanced reports available upon request |

| SHARED FEATURES | Aluminum molds Standard lead time of 15 days or less Tolerances of +/-0.003 in. plus resin tolerance (in./in.) Set-up fees apply to each run |

|

Why Shunjing Prototyping?

- Reduce design risks

- Test multiple designs simultaneously

- Accelerate speed to market

Why On-Demand Manufacturing?

- Manage demand volatility

- Reduce total cost of ownership

- Leverage cost-efficient bridge tooling

Not sure which service is right? Take a complete look at the service options or get quotes for both to compare. You can also call your account representative at +86-755-29729151 to further discuss.

Piece-Part Price Comparison

This chart shares the potential cost savings you can achieve with on-demand manufacturing for molded parts with varying levels of complexity.

| PART COMPLEXITY | SIMPLE | MEDIUM | HIGH |

|---|---|---|---|

| EXTENTS | 1 in. x 1 in. x 0.65 in. | 3.5 in. x 2.5 in. x 1 in. | 4.2 in. x 4.2 in. x 2.9 in. |

| PART VOLUME | 0.16 in.^3 | 2.73 in.^3 | 7.31 in.^3 |

| PIECE-PART PRICING | |||

|

PROTOTYPE |

$1.50 | $2.45 | $7.50 |

|

ON-DEMAND MANUFACTURING SINGLE-CAVITY MOLD |

$1.00 | $1.70 | $5.30 |

|

ON-DEMAND MANUFACTURING |

$0.40 | $0.85 | $2.00 |

Note that this is just an example of parts to illustrate the potential piece-part price savings offered by on-demand manufacturing.